This product connects the wheelset to the frame elastically through the axle box swing arm, adapts to the rigidity requirements of two different axle box positioning in the horizontal and vertical directions, takes into account the stability of high-speed operation and curve passability of the vehicle, and provides flexible support and traction. It is mainly used in the primary suspension of high-speed railways, passenger cars, intercity trains, subways, etc.

Product Performance | Reference Value |

Material | Metal+Rubber |

Composition Materials | Metal + Rubber |

Operating Temperature | -25℃ to 50℃ |

Hardness | 65±5 Shore A |

Axial Stiffness | Determined by design |

Radial Stiffness | Determined by design |

Torsional Stiffness | Determined by design |

Torsion Angle | <15° |

Fatigue Test | Torsion ±8°, 1~3Hz, >1.5 million times |

Dimensions | As per drawing |

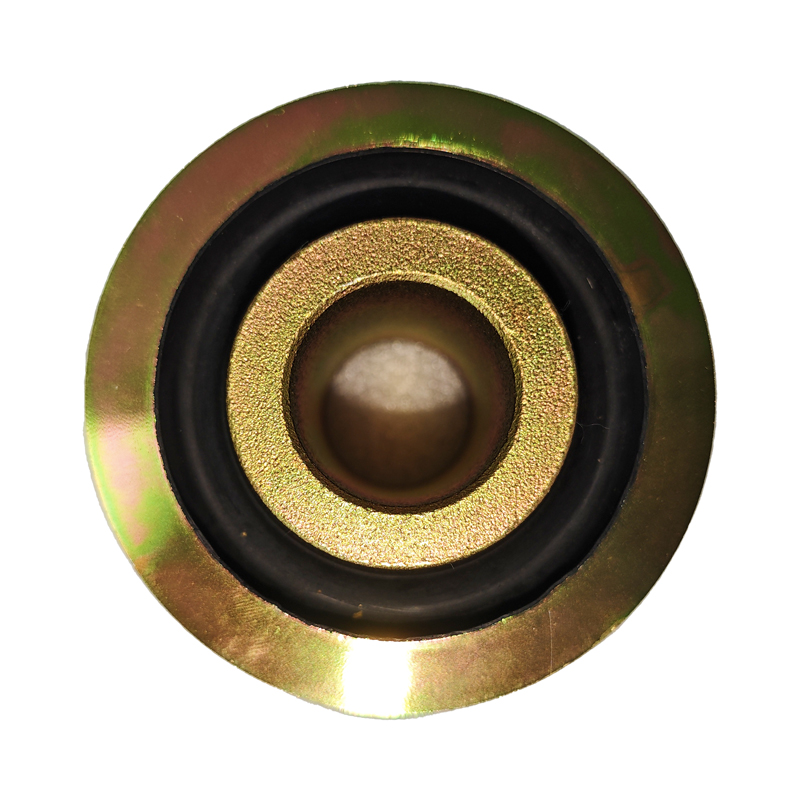

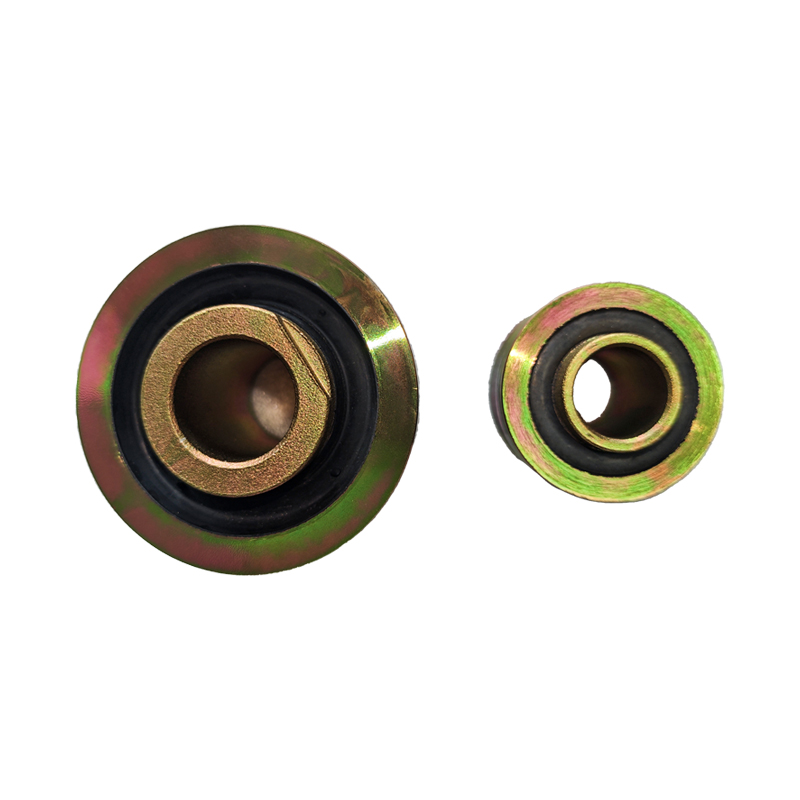

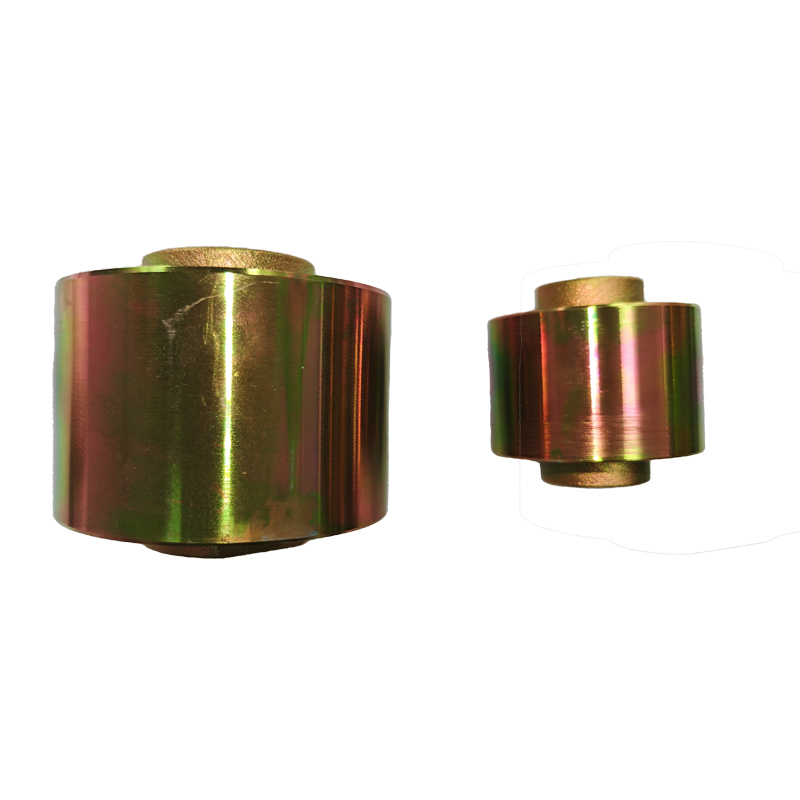

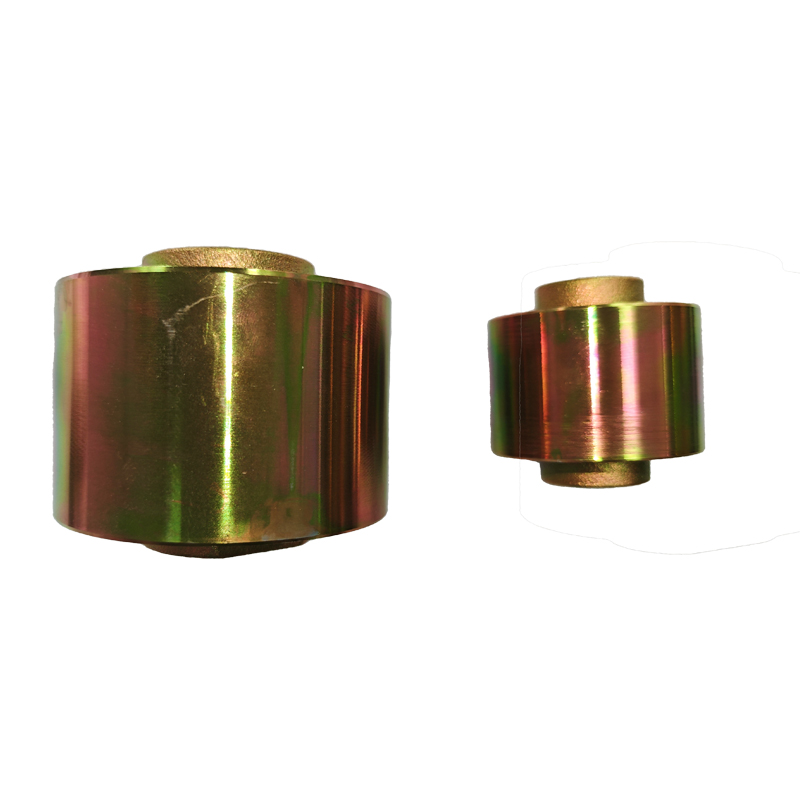

· The metal steel sleeve, mandrel and rubber are vulcanized into one piece. The steel sleeve is available in two types: integral and split.

· A variety of structural options are provided to meet different requirements of radial, axial and torsional stiffness.

· A variety of prestressed designs and manufacturing methods greatly improve the fatigue life of the product.

· Achieve the characteristics of wear resistance and maintenance-free during operation.

· The outer diameter of the product is precisely customized according to the installation hole to ensure a close fit during installation and easy replacement.

· Exposed metal parts can be treated with special coatings such as electroplating, blackening, phosphating, etc. as needed.