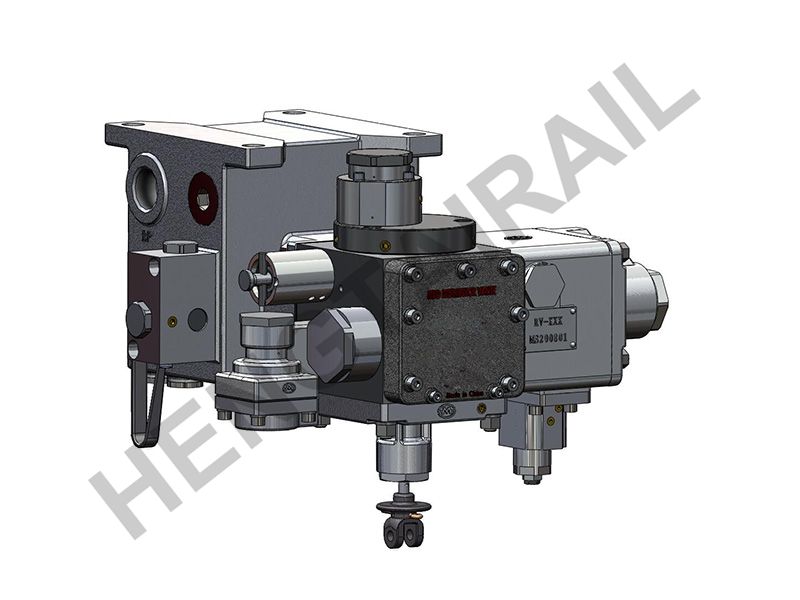

Sensor of HTJZ-A2

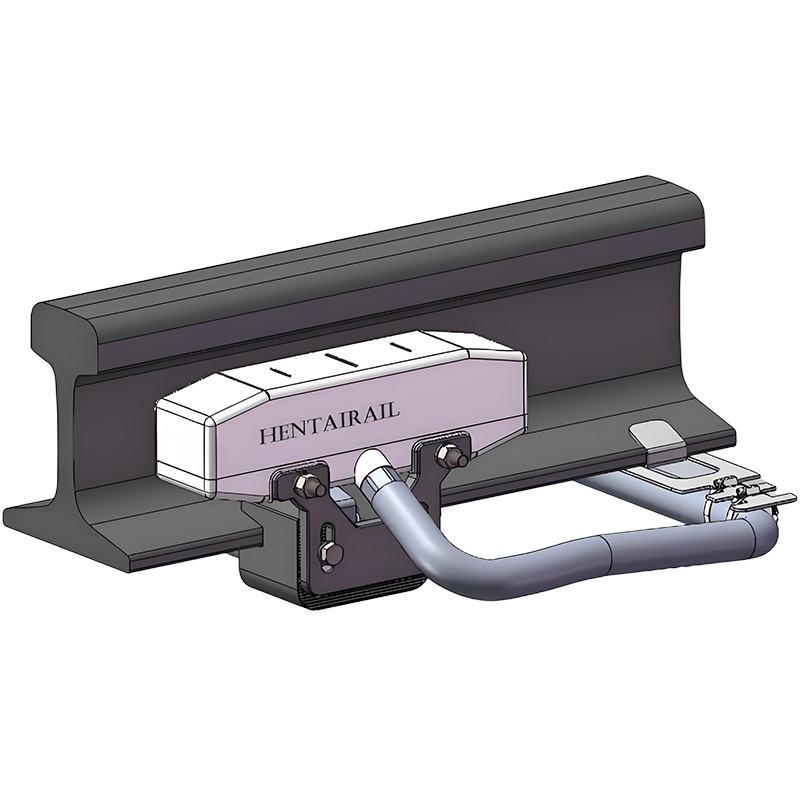

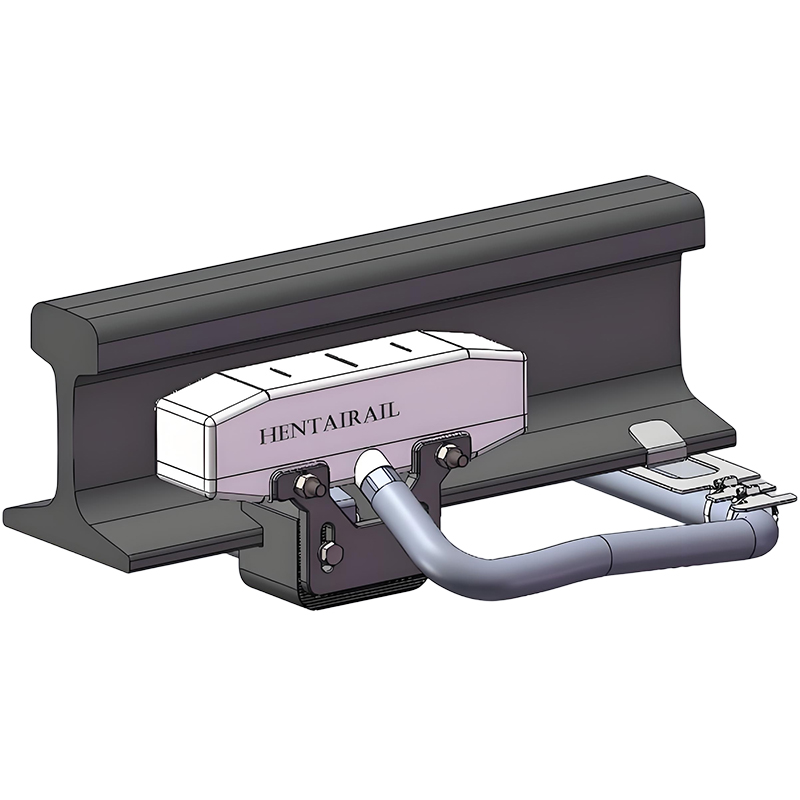

·The magnetic head sensor is a monolithic structure, integrating two magnetic core coils operating at different oscillation frequencies, along with the associated functional circuitry, all encapsulated within a single housing.

·It is mounted on the inner or outer side of the rail using a clamping fixture.

·The sensor features a fully potted (encapsulated) design, providing IP68-rated protection against dust and water.

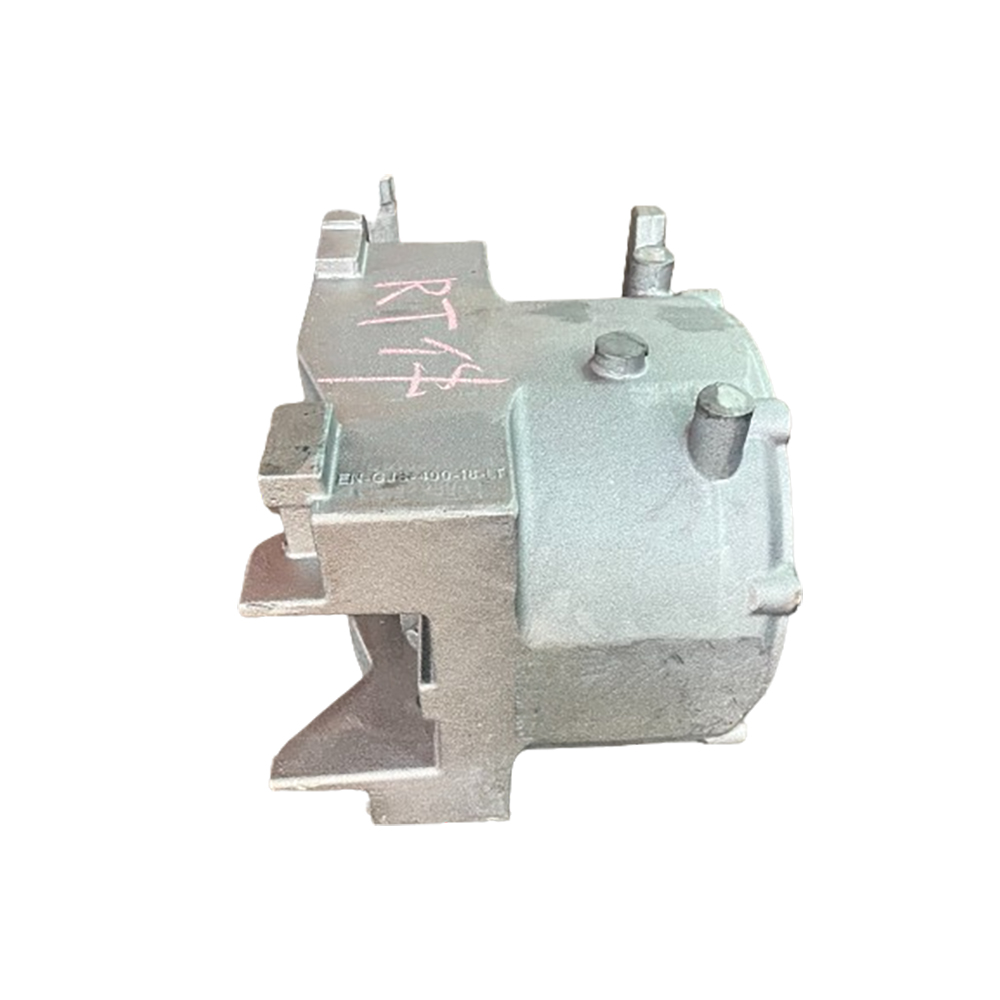

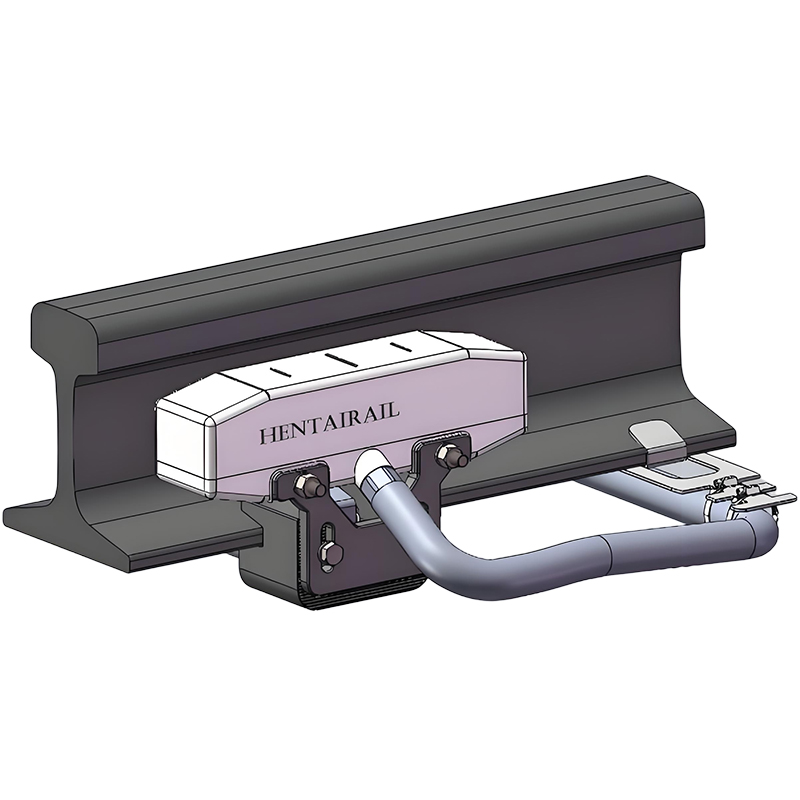

Trackside Junction Box of HTJZ-A2

· The junction box is used to connect the tail cable of the magnetic head sensor to the axle counting cable.

· Inside the junction box, WAGO terminals are used to enable one-to-one connection between the 4-core magnetic head tail cable and the 4-core axle counting cable.

· The junction box is mounted using a bracket, allowing it to be fixed either on the ground or on tunnel walls.

· It features a composite material housing with gasket sealing, providing IP66-rated protection against dust and water.

Technical Advantages

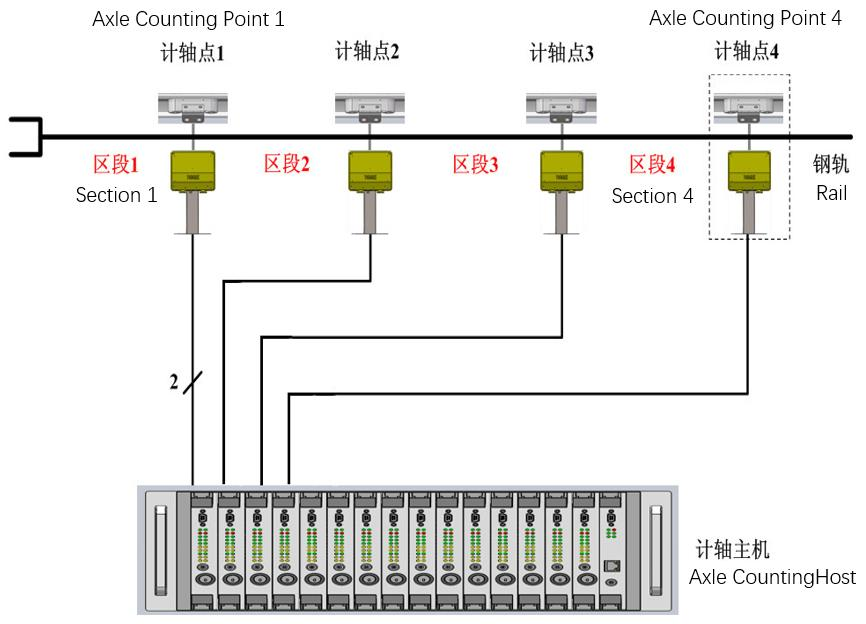

·Simplified Structure: Distributed architecture combined with modular control for streamlined system design.

·Fewer Boards: Minimal board types and reduced quantity, leading to lower complexity and easier inventory management.

·Flexible Configuration: Both software and hardware are easily configurable to adapt to diverse application needs.

·Easy Installation: Clamp-based installation significantly reduces labor and installation time.

·Convenient Maintenance: Precise fault localization and quick board replacement ensure efficient maintenance

·Minimal Fault lmpact: Distributed control architecture localizes faults, limiting impact to individual sections.

·Network Communication Support: Built-in communication interfaces reduce the need for extensive indoor relay wiring, optimizing cabling and saving resources.