The HTSIDT2-3tqme model is a system-integrated display designed to meet the needs of railway system monitoring, capable of displaying train operational status and vehicle parameter information while integrating with PIS (Passenger Information System).

Key Features:

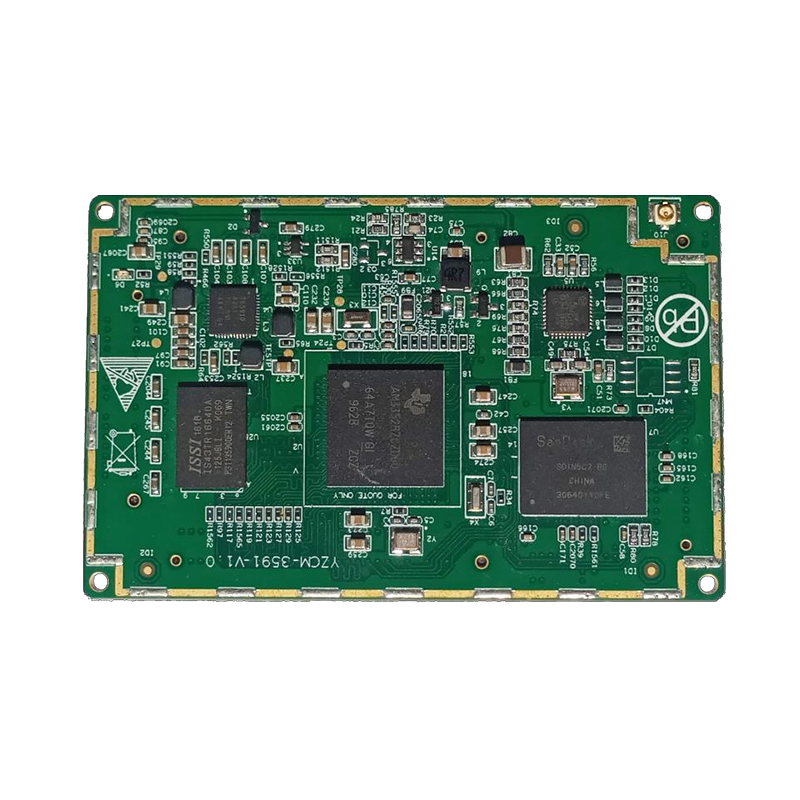

· Performance: 1.8GHz quad-core ARM Cortex-A53 + M4 processor, 2GB LPDDR4, 8GB eMMC storage.

· Display: 15.6-inch, resolution of 1920×1080, with a brightness of no less than 450cd/m².Input Method: Capacitive touch.

· Communication Interfaces: 2 x MVB (EMD), 2 x Ethernet, RS232/RS485.

· Software Platform: LINUX/QNX + QT.

· Main Functions: Temperature management, status indication, image generation, touch control, total communication, brightness adjustment, wireless upgrade, and voice playback.

System | |

Hardware Platform | Intel Atom series |

Memory/Storage | 4GB LPDDR4,16GB EMMC |

Operating System | LINUX, QNX, Windows |

Power Supply | |

Input Voltage | 16V - 100V |

Rated Power | ≤30W (non-heating state) |

Fuse | uilt-in DC fuse |

Display | |

Size | 6.5", 7", 8.4", 10.4", 15.6", 17.3", 21.5" |

Resolution | 640×480, 800×600, 1024×768, 1920×1080 optional |

Brightness | Adjustable 0–800cd/m² |

Backlight Type | LED |

Display Type | TFT-LCD |

Display Standard | Class I (ISO9241-307) |

Input Methods | |

Button Input | Supports up to 80 key inputs, with backlight function |

Touch Input | Resistive, Capacitive |

Communication Interfaces | |

Train Bus | Ethernet, CAN, MVB, Profibus, HDLC |

Serial Port | RS422/RS485/RS232 configurable |

Maintenance Port | Ethernet, USB |

Other Interfaces | |

Audio Input | Two-channel audio output or 2×16W speakers |

Video Input | Supports up to 12 channels;IP video, FBAS analog input. |

Wireless Function | Supports software wireless upgrade |

System Auxiliary Control Unit | |

Indicator Lights | Red, yellow, blue 3-color LED output; yellow LED indicates system status |

Internal Temperature Monitoring | Monitors internal temperature in real-time via sensor; automatically starts |

Ambient Light Detection | Built-in sensor for automatic display backlight adjustment |

Voltage Detection | Monitors multiple internal voltages |

Buzzer | Controls buzzer output,Sound pressure not less than 105 dBA. |

Address Coding | Reads display address code, range 0–7 |

Key Backligh | Reads key value and controls key backlight |

Operating Environment | |

Operating Temperature | -40°C to +70°C, short-term (10 min) up to +85°C |

Storage Temperature | -40°C to +85°C |

Protection Rating | IP65 |

Standards Compliance | EN50155, EN45545, GB/T 25119, etc. |

Product Advantages

· Proprietary Core Technology, Highly Customizable Services:

Backed by proprietary technologies, we deliver customization services that stay tightly aligned with your project milestones—from early-stage concept and design planning, through mid-stage validation and system integration, to final ramp-up and mass production. We support the entire process, including hardware design, software development, vehicle integration, product testing, application support, and full-solution evaluation, ensuring smooth delivery with reduced risk and rework.

· Superior Cost Control and Seamless Replacement of Other Brands:

HTR displays can directly replace existing third-party driver display units without changes to the locomotive's electrical system or operating logic, minimizing retrofit workload and downtime. Product continuity is considered from the very beginning: we ensure long-term availability across the product lifecycle, and our new developments maintain backward compatibility with legacy models for easier maintenance and upgrades. Compared with European brands, total project cost and maintenance expenses can be reduced by approximately 50%.

· Multiple Main Processor Platforms for Diverse Applications:

We offer a broad selection of main processor platforms, including Intel E3800, TI335X, NXP i.MX8, and ROCKCHIP RK3588, enabling the optimal choice based on performance, interfaces, power budget, and system architecture. Moreover, multiple customized designs can be built on the same platform, ensuring configuration and functional compatibility across different display models—simplifying fleet deployment and long-term maintenance.

· Built-in Auxiliary Control Unit for Higher Reliability:

An independent MCU is integrated into the display, decoupled from the main CPU to manage peripheral auxiliary functions and significantly enhance overall reliability and functional safety redundancy. It controls indicator lights, buttons, and buzzer, and also supports internal temperature monitoring, ambient light sensing, and multi-channel external voltage monitoring, ensuring stable and predictable operation.

· Ambient Light Sensor for Automatic Brightness Adjustment:

An integrated ambient light sensor enables real-time reading of external brightness and can be configured to automatically adjust display luminance and keypad backlight, ensuring excellent readability in tunnels, nighttime operation, and strong sunlight—reducing driver visual fatigue.

· High Reliability and High Protection Rating for Harsh Environments:

HTR driver displays provide up to IP65 protection on the front panel, offering strong resistance to dust and water jet cleaning—well suited for harsh rail operating and maintenance conditions. Key components are selected with high-reliability criteria to achieve a high MTBF and minimize lifecycle cost through reduced failures and maintenance.