Train Rubber Side & Center Bearings are key components of the secondary suspension system in railway bogies. Widely applied in locomotives, passenger coaches, and freight cars, these bearings are positioned between the car body and the bogie.

Train Rubber Side & Center Bearings are key components of the secondary suspension system in railway bogies. Widely applied in locomotives, passenger coaches, and freight cars, these bearings are positioned between the car body and the bogie. Their primary functions include:

· Evenly transferring the upper vehicle weight to the bogie,

· Ensuring uniform axle load distribution, and

· Providing essential elastic support and damping to absorb vibrations and shocks during operation.

By effectively isolating vibration and enhancing dynamic stability, they significantly improve ride comfort and operational smoothness across diverse railway applications.

Product Performance | Reference Value |

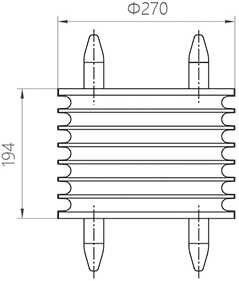

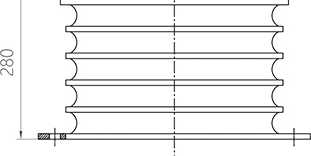

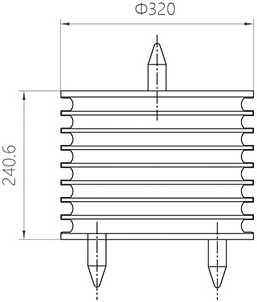

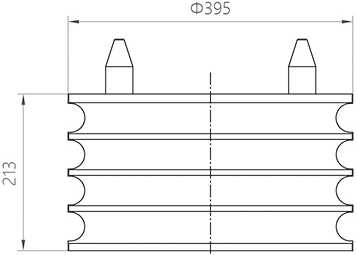

Dimension | Customized |

Material | Rubber/Steel |

Certifications | ISO 9001, UIC 822, DIN 2096, EN 13298 |

Process | Metal Steel Plate and Rubber Vulcanization |

Vertical | P=120.05kN |

Rigidity | 0.1kN/mm |

Hardness | 58±2 Shore A |

Deflection | 16±1.6° |

· Elastic Support & Damping: Provides reliable elastic support to absorb shocks and vibrations during operation, with excellent damping performance to minimize noise and vibration.

· Simple & Durable Structure: Features a straightforward design of vulcanized rubber and metal layers, ensuring easy installation, maintenance, and long-term durability.

· High Adaptability: Customizable to different loads and operating conditions, making it suitable for a wide range of rail vehicle applications.

· Superior Vibration Control: Effectively reduces high-frequency vibrations and improves sound insulation, enhancing ride comfort and operational stability.