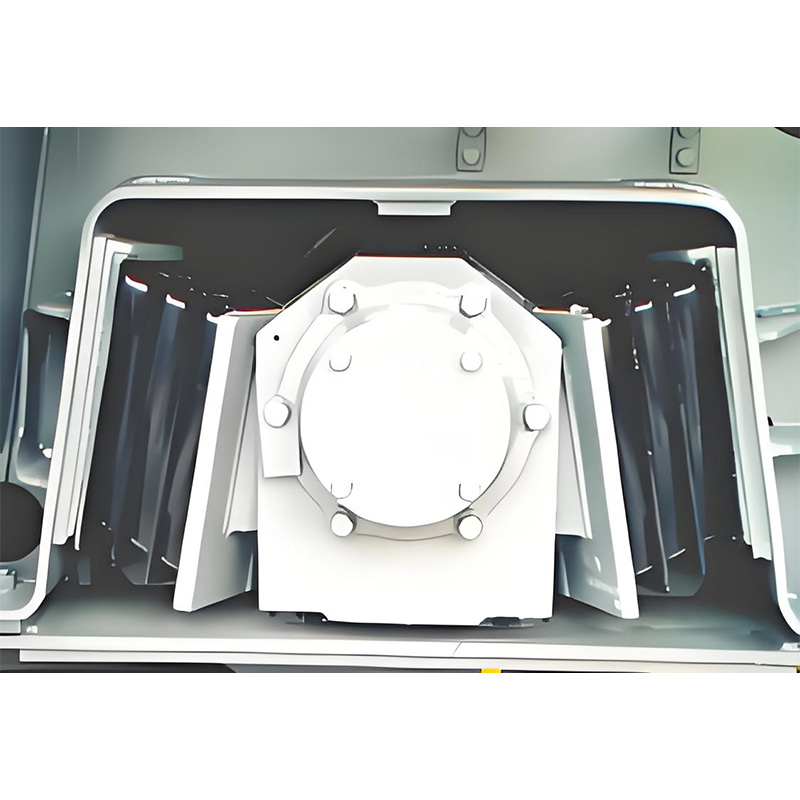

Chevron springs function as a suspension system, providing support to the vehicle's weight and absorbing shocks and vibrations from the road. When the vehicle encounters bumps or irregularities in the road surface, the chevron spring flexes and allows the wheels to move independently, smoothing out the ride.

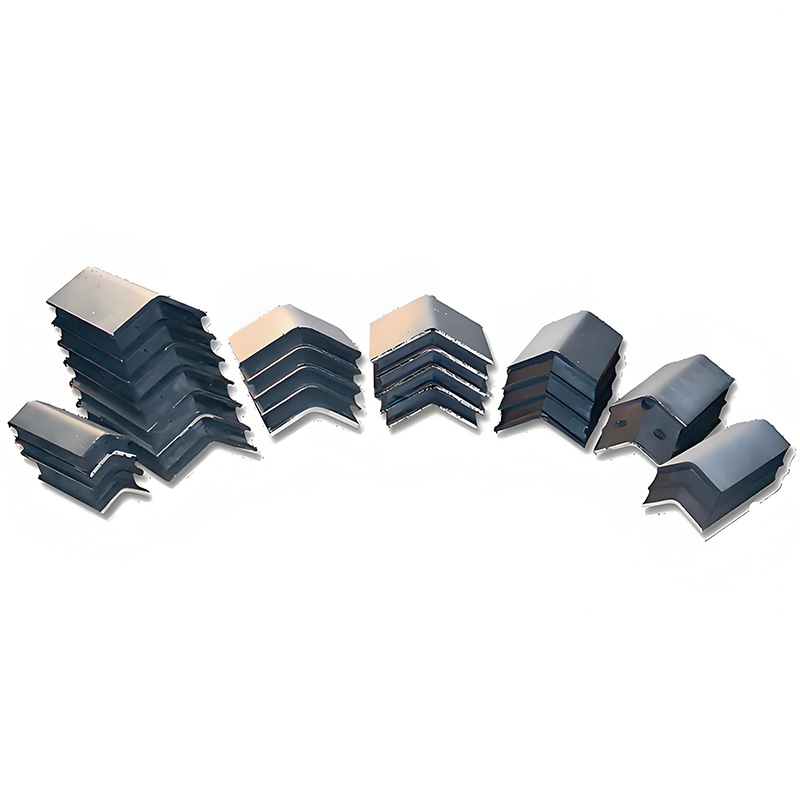

Their design and functionality have been refined over the years to meet the specific needs of different types of vehicles and applications.

Product Performance | Reference Value | |

Dimension | Customized | |

Certifications | EN45545, GB/T 36375-2018 | |

Ozone Resistance | Crack Free; Ozone Density (50±5)*10(-8), 23ºC, 24h, 20% Elongation, Relative Humidity ≤65% | |

Air Oven Aging Performance (70ºC, 96h) | Hardness Change, Shore A | ≤7 |

Tensile Strength Reduction Rate | ≤25% | |

Reduction Rate of Elongation at Break | ≤25% | |

Brittleness Temperature (-40ºC) | Non-Destructive | |

Surface Treatment | Anti-Corrosion | |

Fatigue Test | 2,000,000 Times | |

Storage Temperature | -15ºC to 40ºC | |

Storage Time | ≤24 Months | |

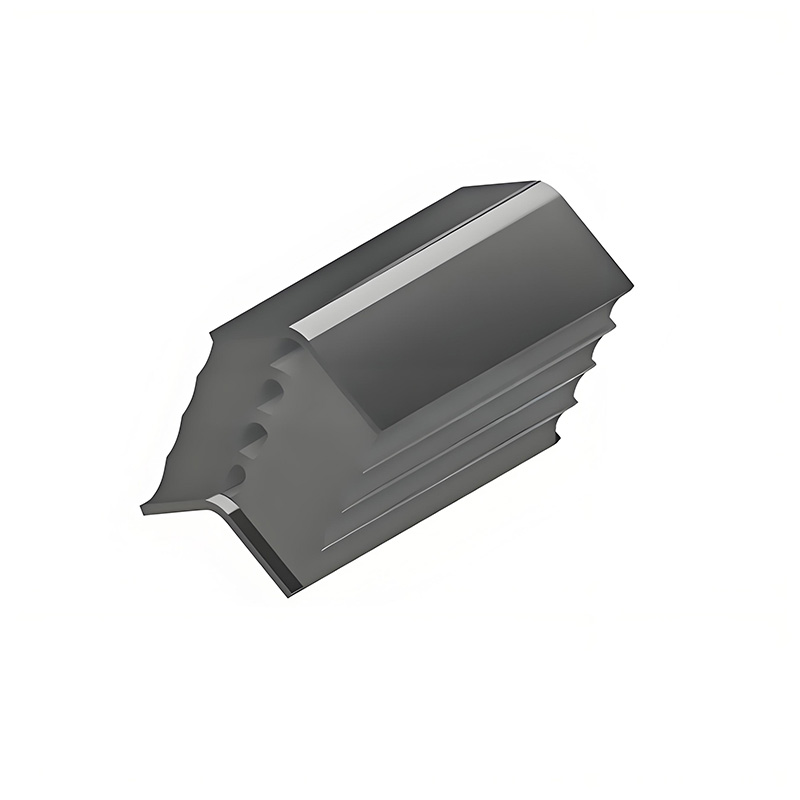

· Design and Structure: Chevron springs are V-shaped, formed by layered spring steel. The V-center connects to the chassis, while the arms link to the axle or wheel.

· Shock Absorption: They support the vehicle, absorb road shocks, and allow the wheels to move independently over bumps.

· Load Distribution: These springs balance vehicle weight on axles for better stability in turns and under heavy loads.