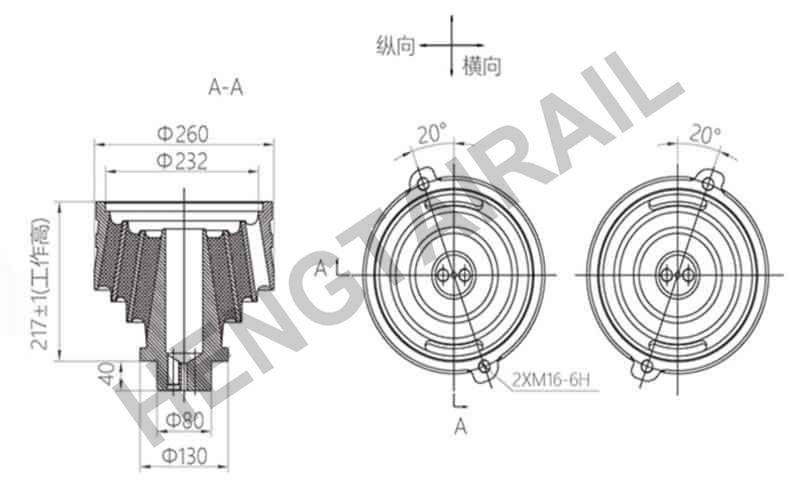

The Conical Spring is named from the shape of rubber layer design. The structure consists of rubber layer and metal.

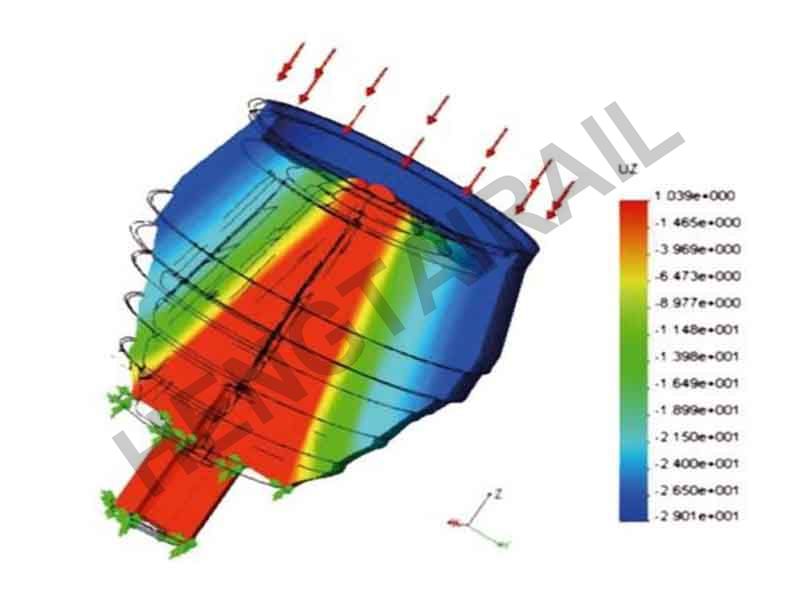

The conical spring is often installed in pairs in one axle box and responsible for providing flexibility in vertical, longitudinal and lateral directions. The vertial stiffness is soft and gets progressively stiffer in order to prevent derailment. The longitudinal and lateral stiffness are important for transferring the braking and traction force as well as for the stability of rail car.

Our conical springs are today running in hundreds of projects all over the world.

Conical rubber spring is installed in primary suspensions system, providing guiding of the axle in longitudinal and lateral directions, and vertical damping with the bogie frame. They also assure homogeneous distribution of loads on the wheels, which is crucial to assure brake and traction performance and to avoid the risk of derailment.

We develops natural rubber formuls, sometims combined with synthetic comounds, to meet the requirements of each porject. We have special formulas which can meet the following requirements:

* Extreme environment and temperature conditions, ranging from -50°C to +60°C

* Extended fatigue life

* Limited creep

* Ozone and ultraviolet protection

All of which have been testd in the best lads and in the field by our cusotmers.

Our rubber-metal solutions conform to the European standard EN45545 for Fire & Smoke Emissions.

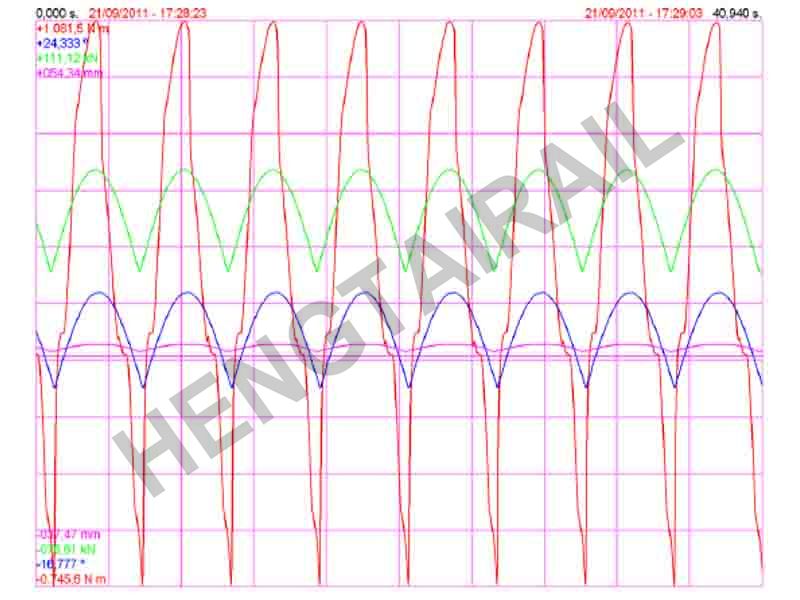

We have test facilities to perform in-house fatigue and creep tests and to measure the mechanical characteristcs of the parts between -50°C to +80°C.

Metal: 45#

Rubber: EPDM or NR

| Brand | C | Si | Mn | P | S | Tensile N/mm2 | Elongation 10% |

| 45# | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 | ≤0.035 | ≤0.035 | ≥600 | ≥16 |

Production Equipment:

Test Equipment:

Advantage:

1. No mechanical friction; No noise;

2. Simple structure;

3. No need for lubrication and maintenance;

4. Enhancing the ride stability, safety and confort of the vehicles;

5. Customization is welcome.

Applications:

1. Railway Wagons

2. Railway Coach

3. Rolling Stock

4. Locomotive

ect.