Product Introduction

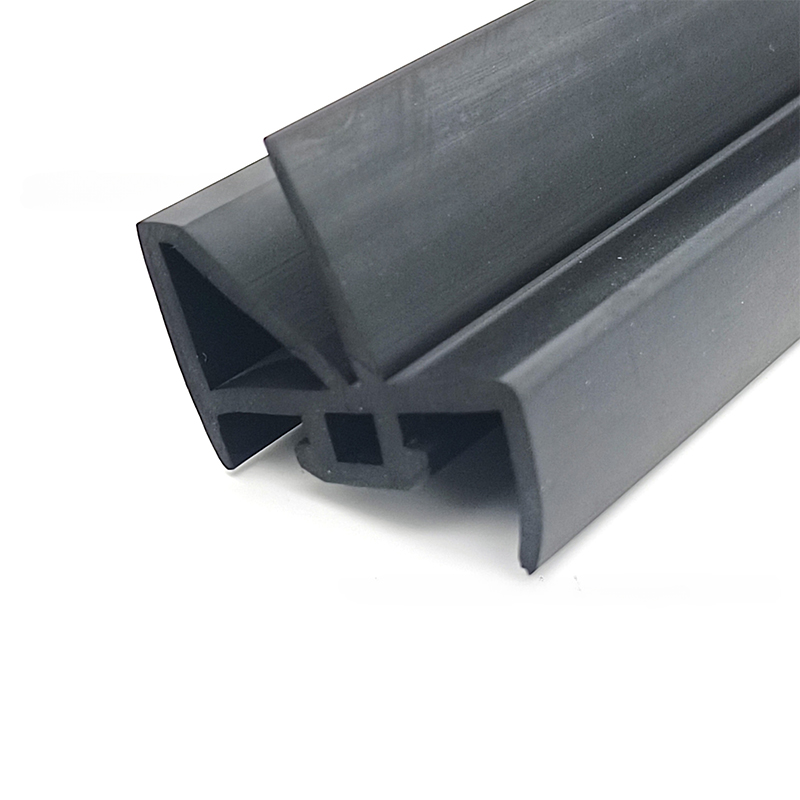

It is a composite sealing strip combining EPDM foam rubber (noise absorption), dense EPDM (waterproofing), and SUS304 dual-steel frame (compression resistance). The main function of this product is to prevent rain/dust intrusion into train cabins, absorb door impact energy and resist permanent compression deformation.

Manufacturing Process

Steel frame pre-forming → EPDM co-vulcanization → Automated extrusion → Weather-resistant surface treatment

Technical Validation

Implemented in Shanghai Metro Line 9 (0 replacements after 3 years / 2,000 daily door operations).

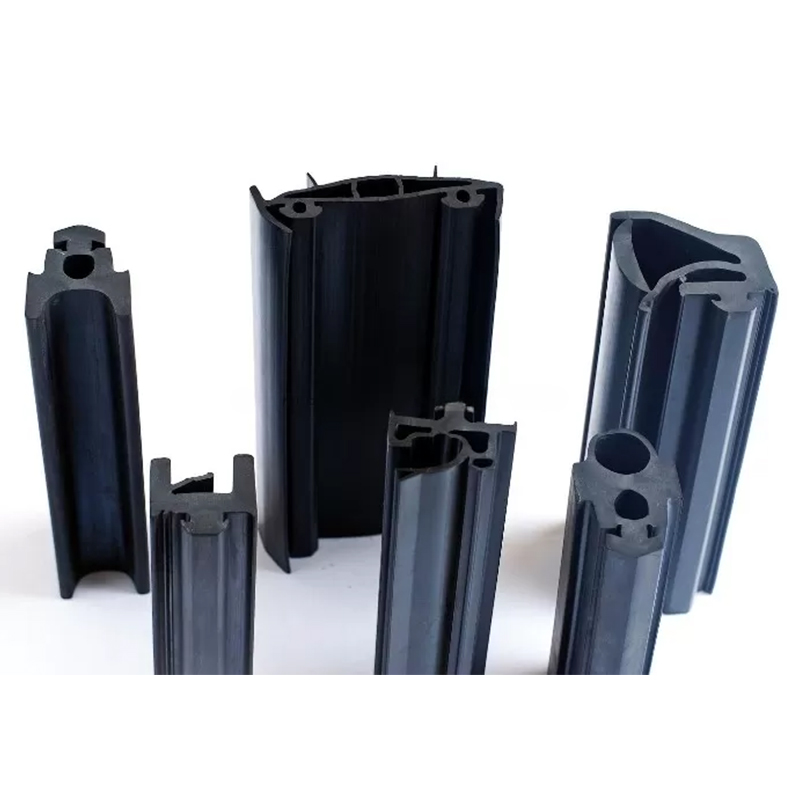

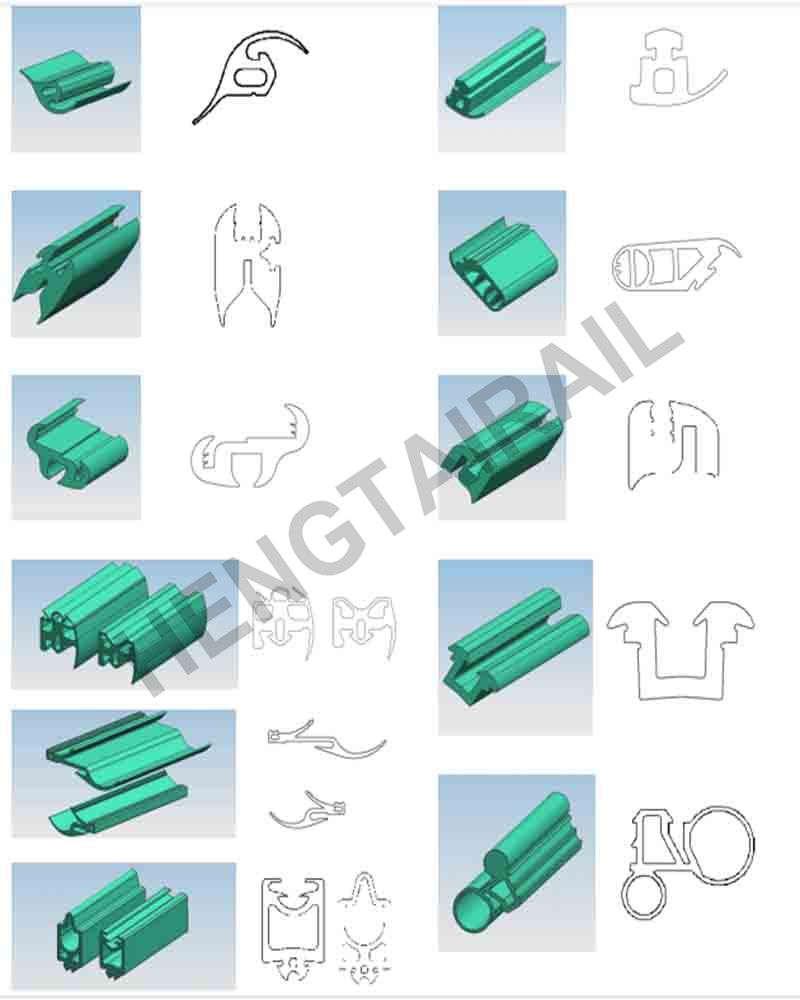

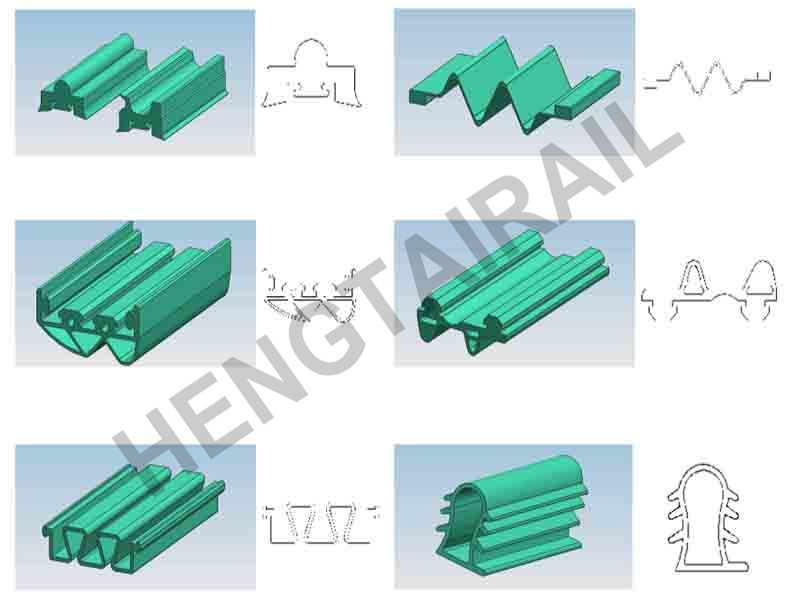

Train Door and Window Sealant Strip Series

Shielded door sealant strip

Mainly used for sealing of shielded doors

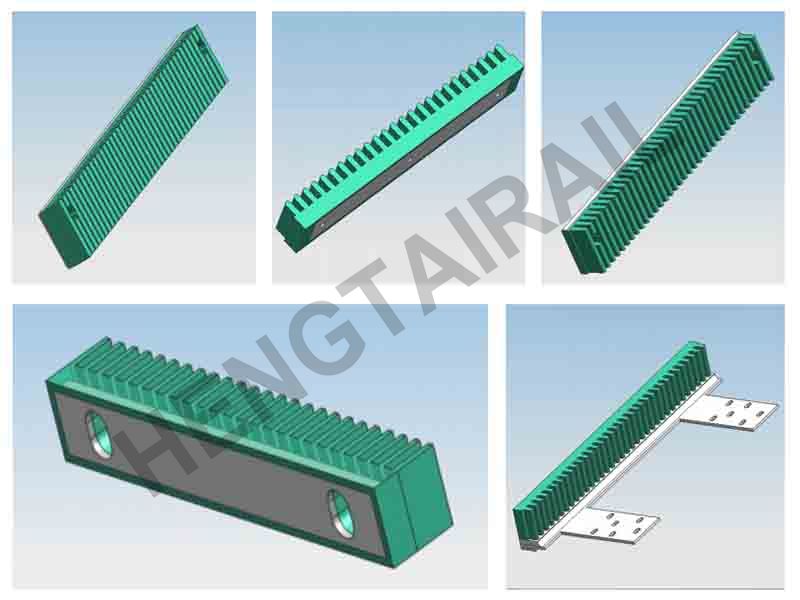

Train Anti trampling

Used for and the gap between the train platform, to prevent air passengers.

Product Performance | Reference Value | Standard |

Fire Resistance | R22-HL3 | EN 45545-2 |

Operating Temperature | -40°C to +120°C | EN 45545-2 |

Compression Set (70°C×22h) | ≤18% | ISO 815 |

Tensile Strength | ≥14.5 MPa | ISO 37 |

Wear Resistance | IP54 | IEC 60529 |

Service Life | >15 years |

· Lifetime Elasticity: Steel frame maintains 100% rebound after 500,000 compression cycles, eliminating door leakage risks.

· Extreme Weather Proof: EPDM resists -40°C ice embedding and +120°C heat aging, outperforming silicone seals.

· Quick Installation: Pre-formed corners with clip-on design cut installation time by 40% vs traditional seals.

· Toxic Gas Control: EN 45545-2 certified smoke toxicity <1.0mg/g, ensuring emergency evacuation safety.