Hydraulic rail lifting jacks are applied for safe rolling stock maintenance, providing precise elevation of locomotives and freight cars up to 300 tons with high-accuracy control.

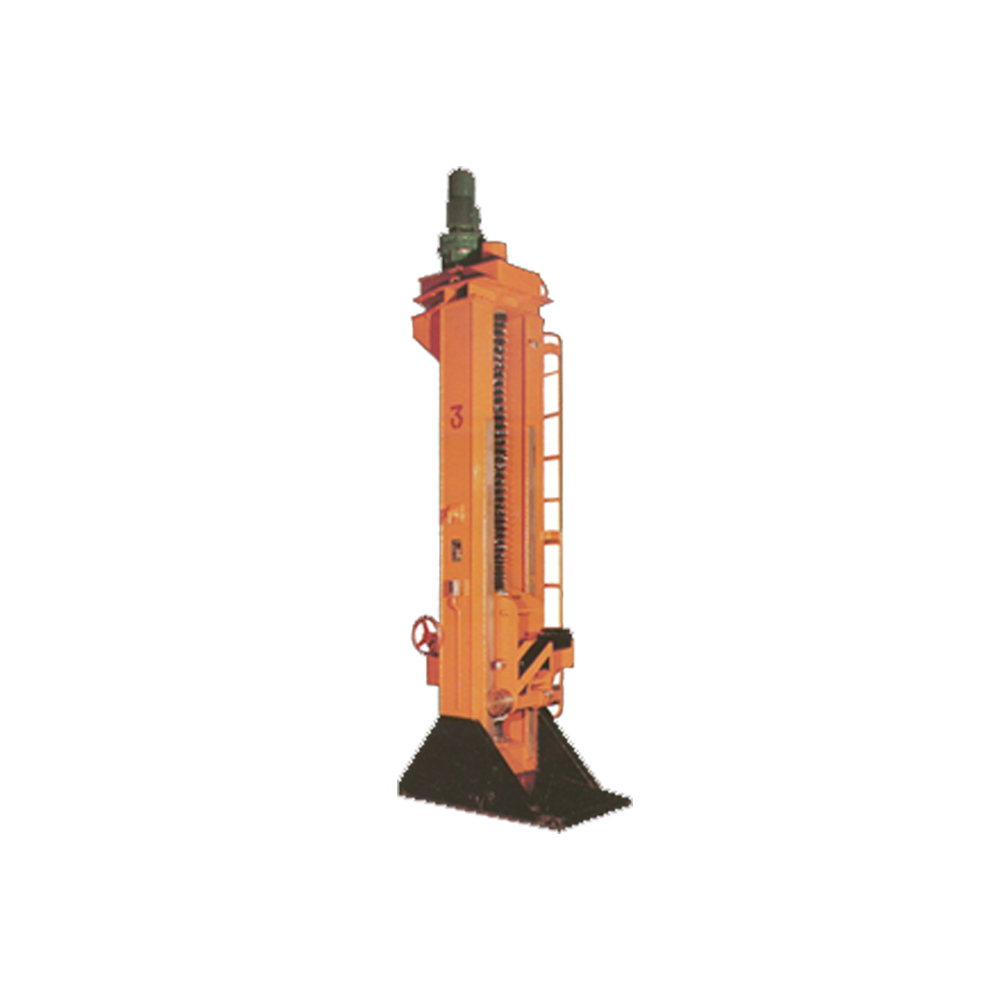

A rail lifting system comprising four hydraulically synchronized jacks capable of simultaneously elevating an entire coach section. The apparatus consists of five core components: structural columns, lifting mechanisms, mobile hydraulic power units, load transfer platforms, and an electrical control system.

Application:

The Lifting jack is mainly used for the maintenance work of the construction vehicle to facilitate the maintenance and replacement of the bogie and other parts.

It is used for railway vehicle manufacturing companies and repair units to repair and replace the bodies, bogies and other parts of rail vehicles.It is not limited by the vehicle type, and can lift various types of vehicles, greatly improving the inspection and repair capabilities of hybrid vehicles.

The equipment shall be suitable to work under below conditions:

Ambient temperature: -15℃~+55℃

Relative humidity: ≤90%

Altitude: ≤2000m

Single Lifting capacity:15T - 40T

Function | Description | ||

Total Lifting Capacity | 60 t | 140 t | 160 t |

Lifting Capacity of Per Jacket | 15 t | 35 t | 40 t |

Minimum Lowering Height | 400 mm | 400 mm | 800 mm |

Maximum Lifting Height | 2000 mm | 2000 mm | 2600 mm |

Minimum Distance from Track Center Line to Jack Load Platforms | Customized | 1200 mm | 1310 mm |

Speed | 220 mm/min | 180 mm/min | 285 mm/min |

Drive Method | Electric | Electric | Electric |

Electric Motor Power | 3 kW | 5.5 kW | 7.5 kW |

Rated Voltage | 380 V | 380 V | 380 V |

Rated Frequency | 50 Hz | 50 Hz | 50 Hz |

Noise | ≤65 db | ≤75 db | ≤75 db |

Synchronization Deviation | ±3 mm | ±3 mm | ±3 mm |

Dimension for Single Jacket (L*W*H) | 500*1000*2450 mm | 1700*1050*4000 mm | 1450*1300*3450 mm |

Weight (Total 4 Jackets) | 1500 kg | 6500 kg | 7600 kg |

· Dual Control System: Each hydraulic lifting jack operates via an independent control box, while a central console manages synchronized operation of all four units.

· Safety Interlock Protocol: Independent jack controllers interface with the main console through hard-wired interlocks, using open-run or conduit-protected cabling.

· Precision Drive Performance: All jack motors maintain rotational speeds within ±16 RPM of rated values, ensuring responsive elevation/lowering with synchronized motion control.

· Dual Mobility Configuration: Wheel-mounted bases enable manual workshop positioning, while integrated lifting lugs permit crane relocation.

· Adjustable Lift Range: Each jack provides infinite height adjustment within its engineered stroke limits.