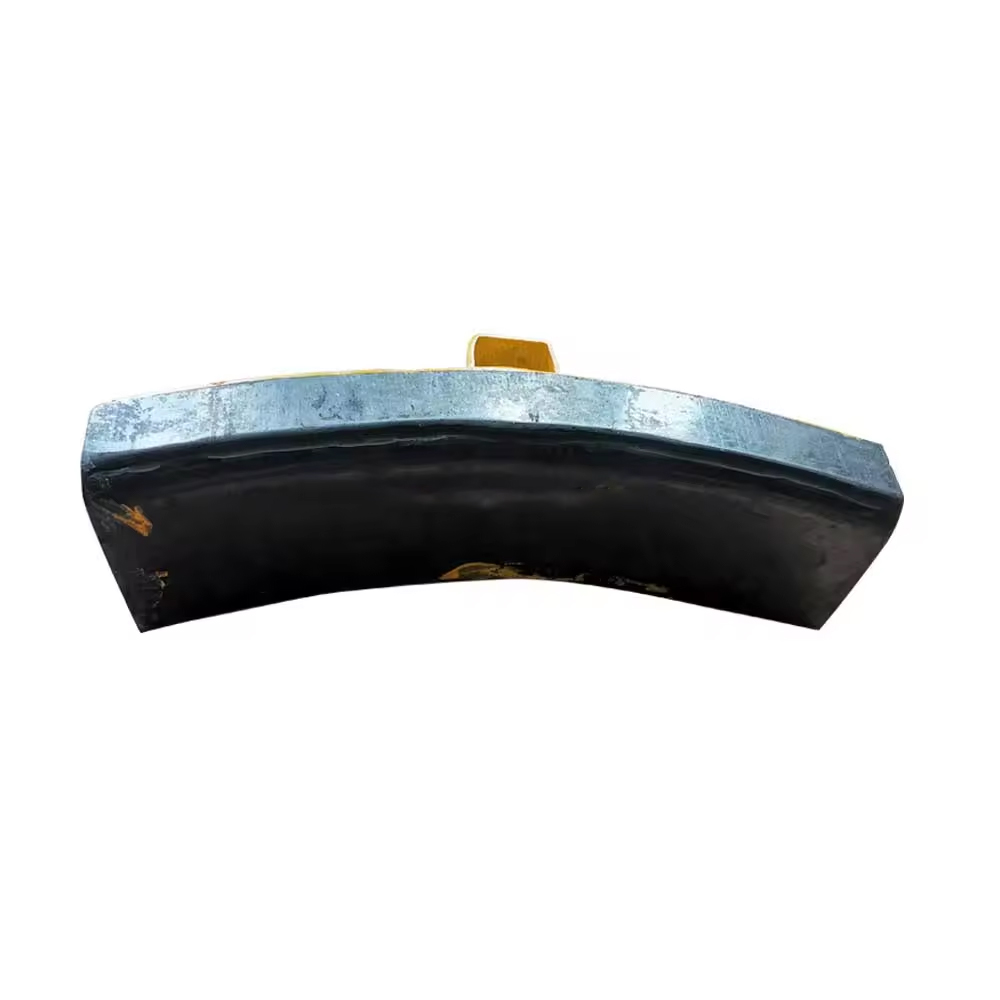

When the train is running and braking, the brake part that directly rubs the wheel to stop the train is the brake shoe; the tile shaped brake block made of cast iron,composite material or other materials holds the wheel tread tightly and makes the wheel stop rotating through friction.

Railway brake shoe other name is railway brake block, train brake block. It is mainly used for the braking of heavy-duty freight cars. It is applicable to railway freight cars with maximum running speed of 120km/h and axle load of no more than 25t.

Composite brake shoes for railway freight cars are divided into two types: one is high friction coefficient composite brake shoe(H), and the other is low friction coefficient composite brake shoe(L). “H” brake shoe cannot be interchanged with “L” brake shoe and various cast iron brake shoes.

“H” brake shoe is suitable for railway freight cars with speed no more than 120km/h and axle load no more than 25t;

“H” brake shoe is divided into the following two type:

· The Φ915mm brake shoe is suitable for wheels with a nominal diameter of Φ915mm

Product Performance | Reference Value | |

Material | Composite | |

Inspection | Domestic or Appointed | |

Braking Force | High Friction (2.8~3.2) | |

Density(g/cm3) | Not more than ± 5% | |

Rockwell Hardness | ≤100HRR | |

Impact Strength(kJ/m2) | ≥3.0 | |

Compression Modulus(MPa) | ≤1.3×103 | |

Compressive Strength(MPa) | ≥25 | |

Bending Strength(MPa) | ≥8 | |

Application | Railway wagon, passenger car ect. | |

Speed | Using for 80-120km/hour | |

Average Friction Coefficient | Brake Shoe Thrust (kN) | 10 |

Average Friction Coefficient(u) | ≥0.25 | |

Instantaneous Friction Coefficient | Instantaneous Friction Coefficient(u) | ≥0.38 |

Yield Strength(Mpa) | ≥235 | |

Tensile Strength(Mpa) | ≥370 | |

Elongation After Fracture | ≥26% | |

“L” brake shoe is applicable to railway freight cars with a speed of no more than 90km/h and a axle load of no more than 21t.

Product Performance | Reference Value | |

Material | Composite | |

Inspection | Domestic or Appointed | |

Braking Force | Low friction(1.7~2.2) | |

Density(g/cm3) | Not more than ± 5% | |

Rockwell Hardness | ≥30HRR | |

Impact Strength(kJ/m2) | ≥1.8 | |

Compression Modulus(MPa) | ≤1.5×103 | |

Compressive Strength(MPa) | ≥25 | |

Bending Strength(MPa) | ≥8 | |

Application | Railway locomotive, railway wagon, passenger car ect. | |

Speed | Using for 80-120km/hour | |

Average Friction Coefficient | Brake Shoe Thrust (kN) | 20 |

Average Friction Coefficient(u) | ≥0.1 | |

Instantaneous Friction Coefficient | Instantaneous Friction Coefficient(u) | ≥0.21 |

Yield Strength(Mpa) | ≥235 | |

Tensile Strength(Mpa) | ≥370 | |

Elongation After Fracture | ≥26% | |

· Customized according to customer requirements

· Friction property can be adjust according to requirement.

· Good wear resistance and long life span.

· Its no Crocidolite in Ironstone(asbestos).

· It contains no lead, zinc or any other toxic materials,

· it is environmental friendly, and causes no bad smell in friction.