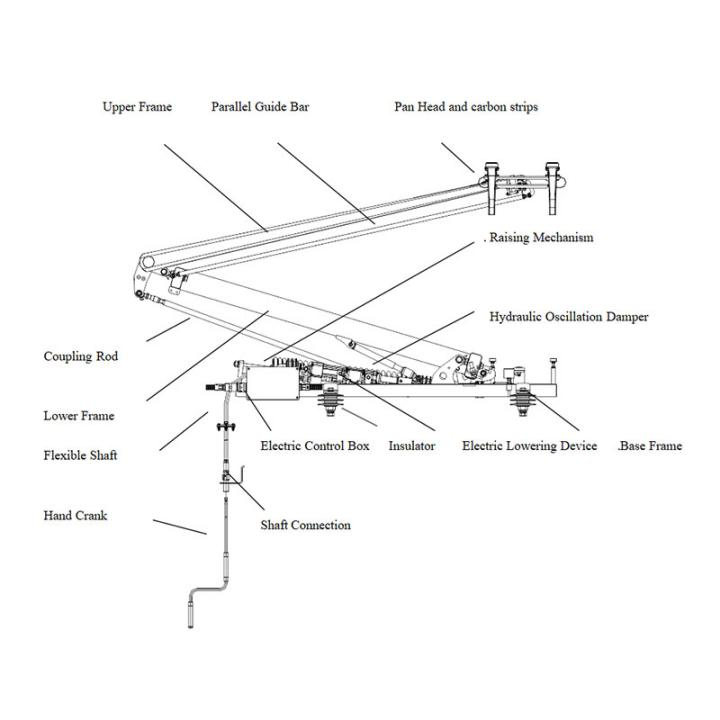

As a key current collection device for electric locomotives and EMUs, the single-arm pantograph maintains continuous sliding contact with the overhead catenary wire through the carbon strip, transmitting 25kV (or other voltage levels) of high-voltage electrical energy to the train's traction system, while also accommodating dynamic displacement and vibrations during high-speed operation.

·Our objective was to design and manufacture a simple, light weight, and easy to maintain Pantograph.

·We further wanted to achieve the optimum in catenary contact behavior, even under the most basic and adverse overhead wire conditions, and combine with it a maximum of operating safety.

Product Performance | Reference Value |

Product Name | Pantograph |

Temperature | -35℃~+65℃ |

Speed | 120 km/h |

Nominal System Voltage | 1500 VDC |

Operational Current | 1050 A |

Max Operational Current(30s) | Max 1600 A |

Static Current | Max 460 A |

Rising / Lowering Time | ≤10 s |

Maximum Working Height | 2800mm (with insulators) |

· Low weight:Reduces the overall load on the vehicle roof, improves energy efficiency.

· Simple construction:Reducing the risk of mechanical failure and simplifying assembly, disassembly, and training for maintenance personnel.

· Minimum maintenance: Requires very little upkeep over its service life, lowering operational costs and downtime.

· Excellent contact behavior: Even under basic catenary conditions.