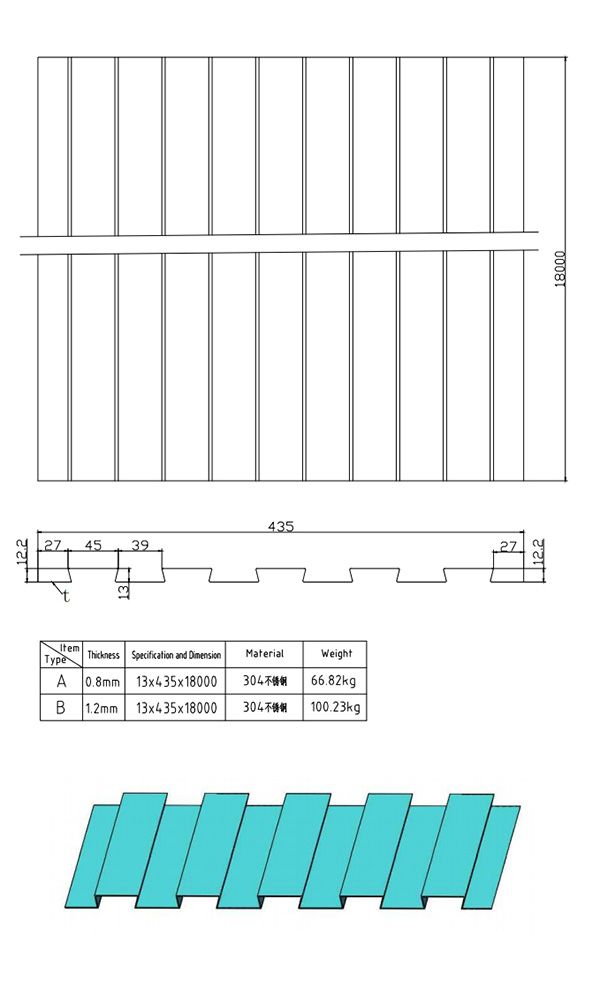

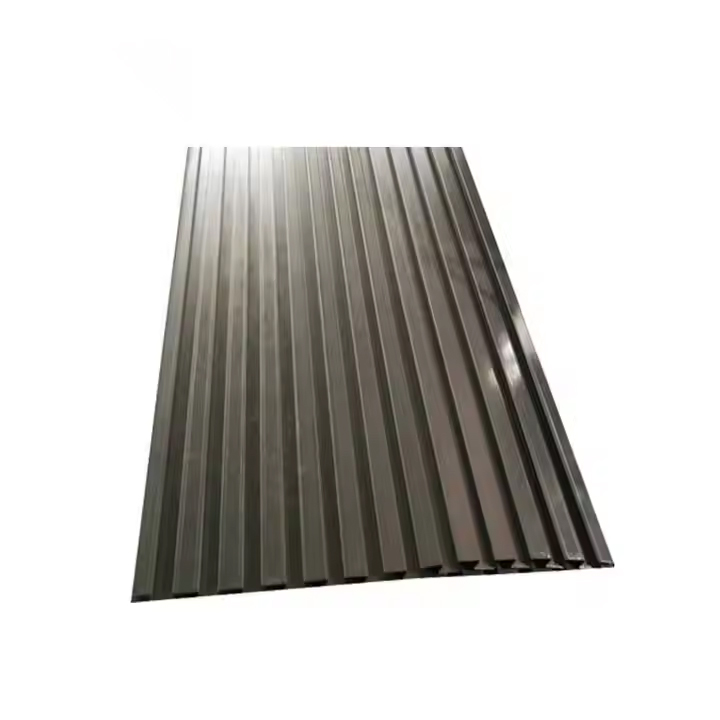

Mainly designed for applications in passenger trains, our structural corrugated panels deliver diverse functionality in ceilings, lavatories, and galley walls. For large-sized plates, we use hoisting machines for stamping and bending. Our standard sheet length is 3 meters. Before starting mass production after the first sheet stamping, we will conduct a lot of sheet experiments and adjust the machine at the same time until the customer's bending requirements are met.

Key Parameter | Thickness 1.0mm | Thickness 6.0mm | Thickness 10.0mm |

Thickness Accuracy | ±0.15mm | ±0.30mm | ±0.50mm |

Load Capacity | 1.2 kN/m² | 15.0 kN/m² | 25.0 kN/m² |

Application | Ceiling Panel | Galley Floor | Maintenance Platform |

Vibration Reduction | 83%+ | 90%+ | 93%+ |

Installation Rate | 40 m²/hour | 22 m²/hour | 15 m²/hour |

Test Standard | TB/T 3355-2021 | ||

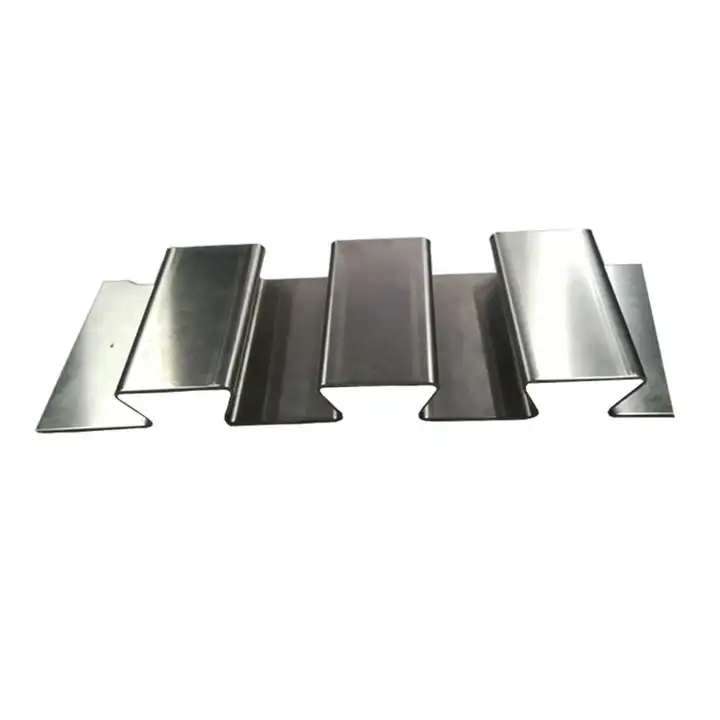

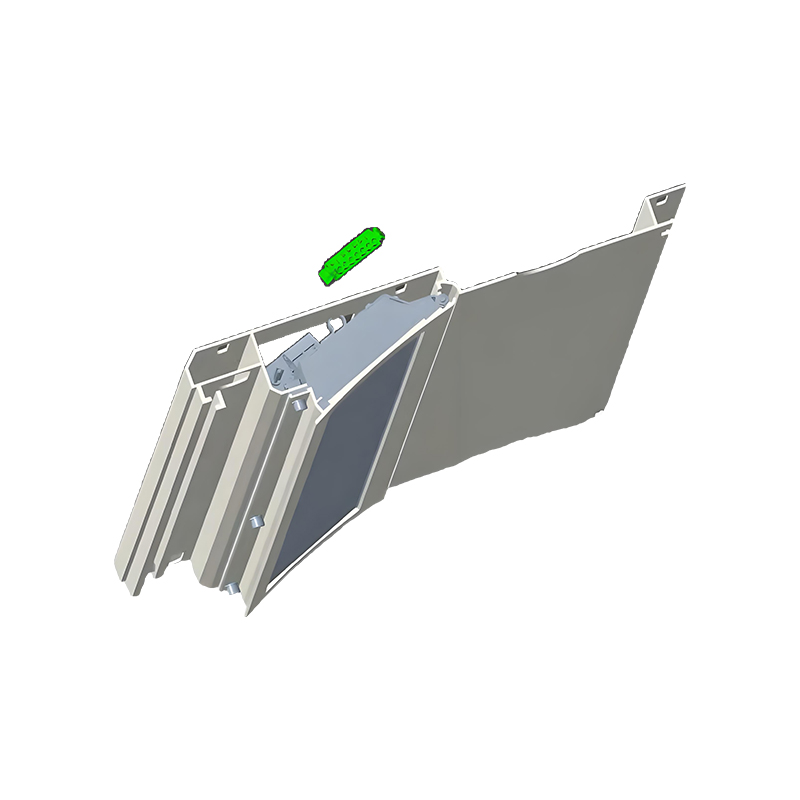

· Intelligent Space Optimization: Deep corrugations create slim yet robust channels for ventilation ducts, lighting tracks, and data cables, turning ceiling voids into organized pathways.

· Invisible Resilience: The ripple effect absorbs shocks from track irregularities, reducing noise transmission while preventing fatigue cracks.

· Aesthetic Integrity: Seamless brushed or coated finishes maintain cabin elegance, concealing critical infrastructure behind sleek, maintenance-free surfaces.